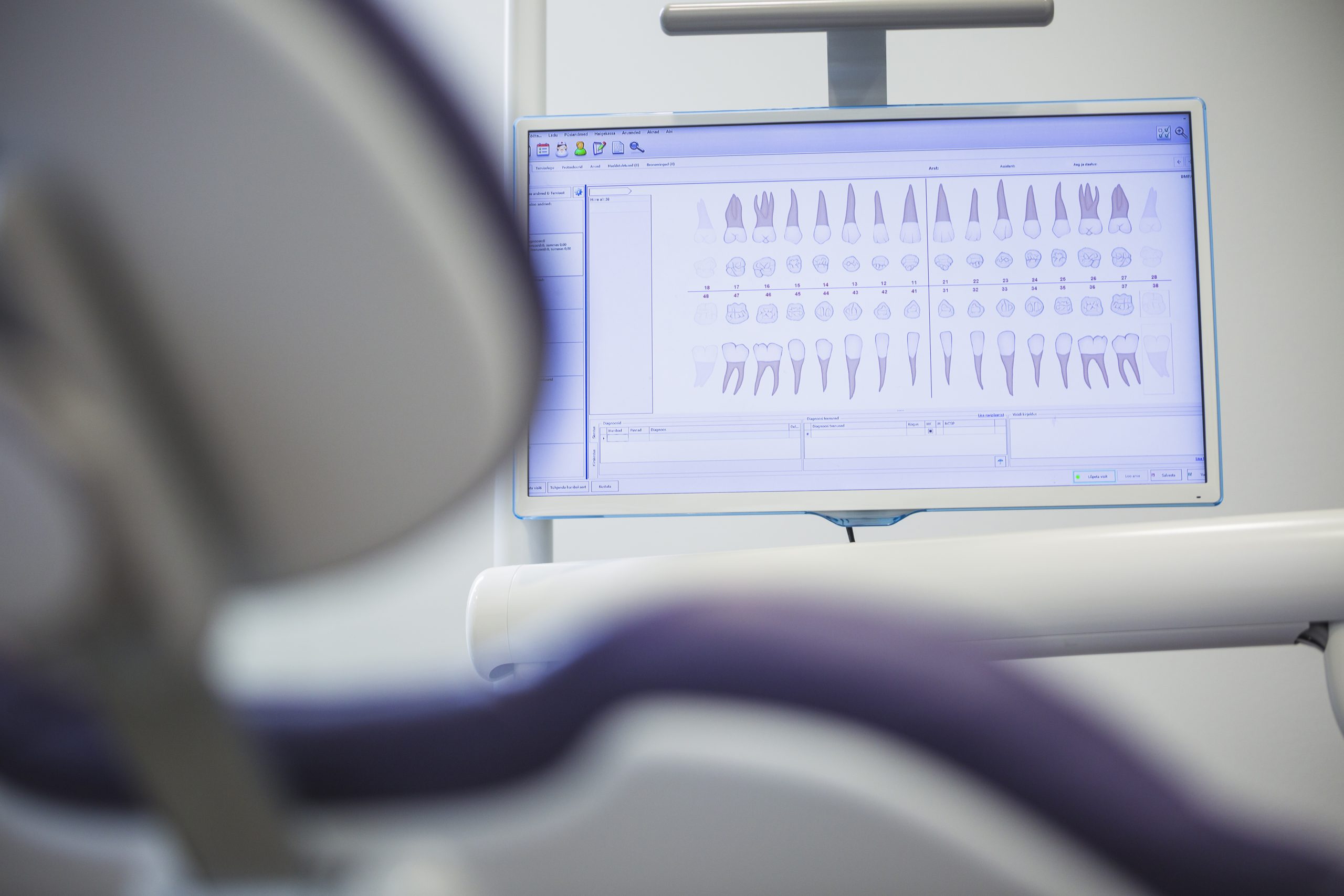

The ideal digital impression would allow the ability to scan just the quadrant or the entire arch (Figure 27-11), allow for fabrication of all types of dental restorations, and even allow for subgingival preparations. Use of such advanced technology produces an accurate 3D image of the object being scanned in virtual real time. The clinician is able to view the 3D replica when the scanning procedure is complete.

The iTero intraoral laser scanner by Cadent Align Technology, Inc. consists of a mobile cart on wheels that can be moved to different operatories23 (Figure 27-12). The handheld laser scanner (wand) releases a light stream of compressed air during the scanning procedure to prevent fogging of the lens that is attached to a proprietary data cable (Figure 27-13). The data cable is attached to a computer with a liquid crystal display (light-emitting diode [LED]) monitor that processes the electronic information. A wireless keyboard, mouse, foot pedal, and analytical instruments that are proprietary to the manufacturer control the entire digital scanning process.

The wand uses parallel confocal imaging to capture a 3D digital impression.24,25 It emits a beam of laser light through a small hole and directs it toward the tooth surface. Only an object at the proper focal length will reflect light back through the filtering device.10 The camera covers a 14 mm2 × 18 mm2 area at a scan depth of 13.5 mm.26 No reflective medium is required for the laser light to be reflected from intraoral surfaces. It does not have to be held a fixed distance from the tooth and will scan when touching the teeth.24 The foot pedal is used to activate the wand to capture successive images. After each scan, the option to accept or reject the scan is presented to the clinician. After being accepted, the scan is integrated into the digital model. The unit also provides visual and verbal prompts for active guidance during the digital impression process.25

The software prompts for a series of five scans (occlusal, facial, lingual, mesioproximal, and distoproximal views) per prepared tooth or abutment, with additional scans required for the adjacent teeth and opposing dentition. The usual series may range from 15 to 30 scanned images to record the preparation, opposing teeth, and the occlusal relationship.10